-

2

R&D centre

-

5

Design & Engineering centre

-

3

Transfer of Technology (TOT)

-

250+

Engineers

JNV Ventures Group’s R&D philosophy is driven by its Mission to create sustainable value for its customers by integrating and localising global technologies and solutions with market-relevant insights, and a keen understanding of the automotive and various sectors. Underpinning the Group’s R&D philosophy are also the Values and the Vision of the Group.

The Group has been able to provide suitable and cost-effective R&D solutions to customers because of the inherent strengths of the R&D establishment. It has taken on board some of India’s & International top-notch talent in R&D. This has helped the Group to set and meet with global benchmarks in each segment of its diverse operations and delight both domestic and global customers, and other stakeholders.

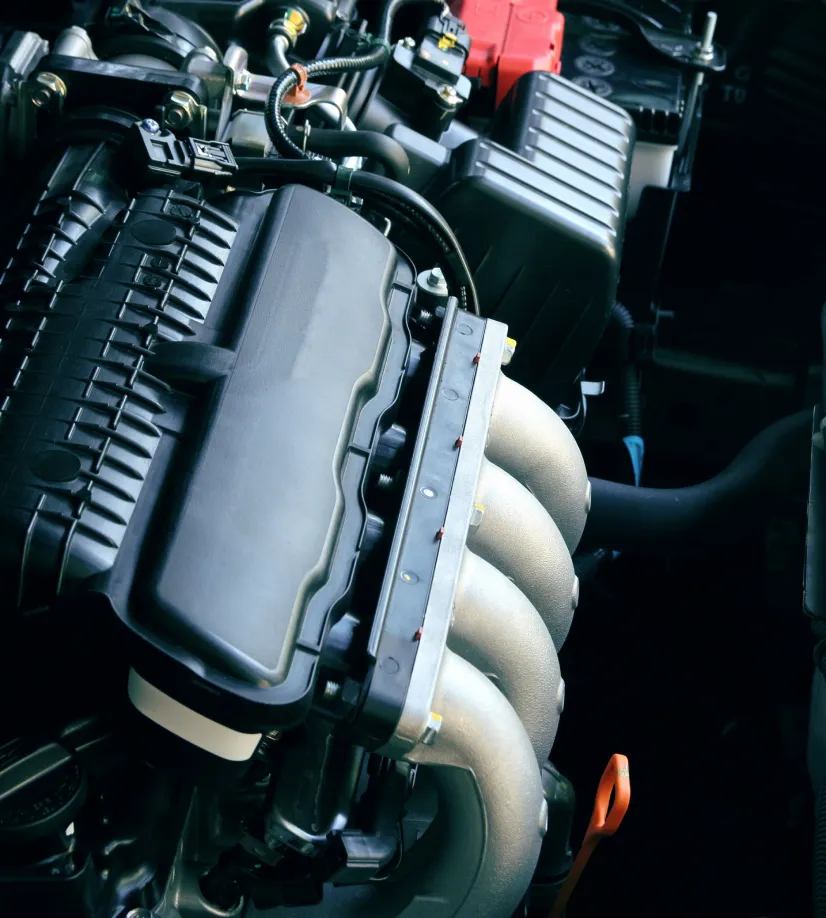

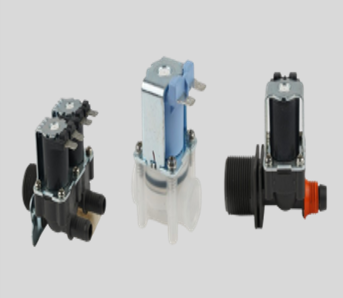

The Group’s commitment to excellence makes it the preferred choice by OEMs for a range of products and solutions in automotive plastics and polymers, fluid transmissions, emission parts, anti-vibration solutions, sealing systems and a range of other rubber-based solutions.

The highlights of our R&D include:

The JNV Ventures Group’s R&D facilities track global developments in automotive technology. It has made significant investments in machines and equipment to ensure that it offers customers the latest in technology and solutions that work to benefit the customer base. The Group has enabled customers to respond to changing product line developments.

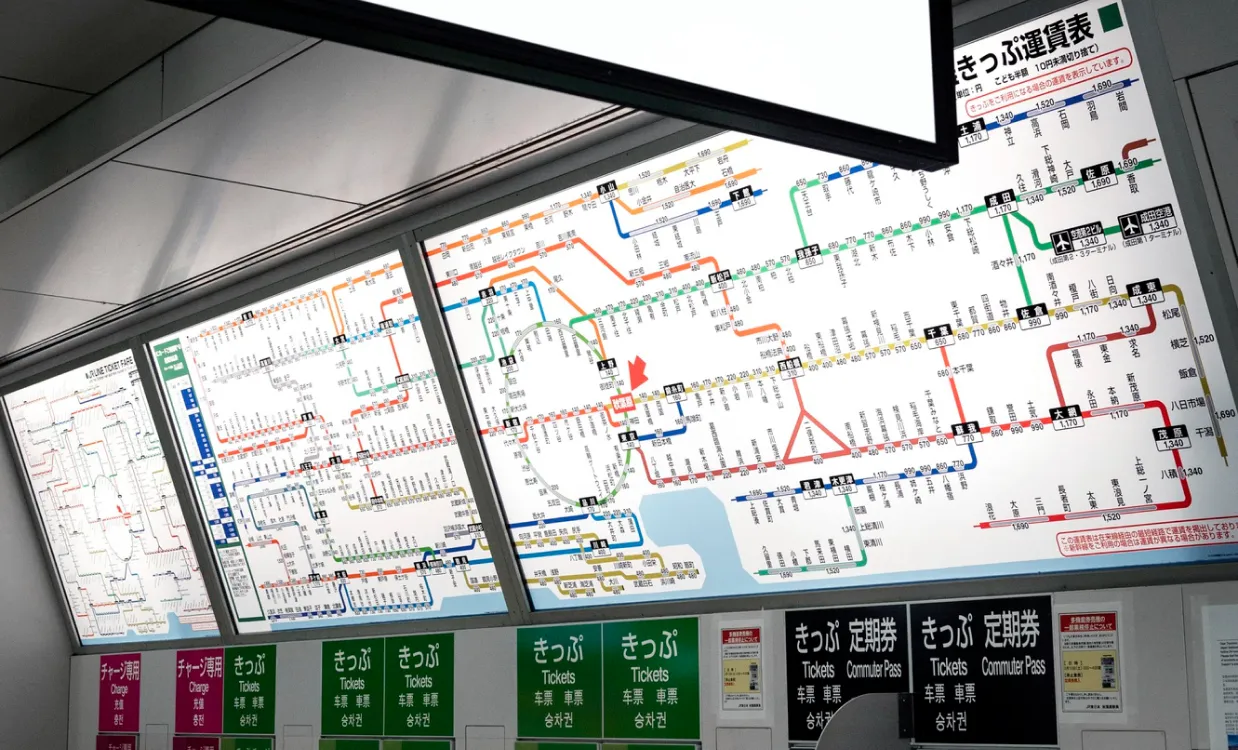

JNV Group as a strategy of backward integration has established a world class Central Engineering center that offers standardized processes & strategies for New Product Development. This engineering room is the backbone of our production processes.

Tooling is an important process in the component manufacturing industry today. Every single component requires a unique tool and once the product design of a new part is finalized, it is then sent to the central engineering centre for feasibility, tool designing & manufacturing.

The JNV Group understands that its customers are best served with a centralized design & engineering function that offers our diverse customer base the following capabilities:

Our growing centralized engineering center has the following equipment: VMC machines (2 Nos.) CNC lathe (1 No.) CNC EDM (1 No.), conventional EDM (1 No.) Surf grinder (1 No.); other machines (6 Nos.) .

The software licenses we use includes Siemens NX 10, CREO CAD, CREO TD, DELCAM, Top Solid and Abaqus (FEA).